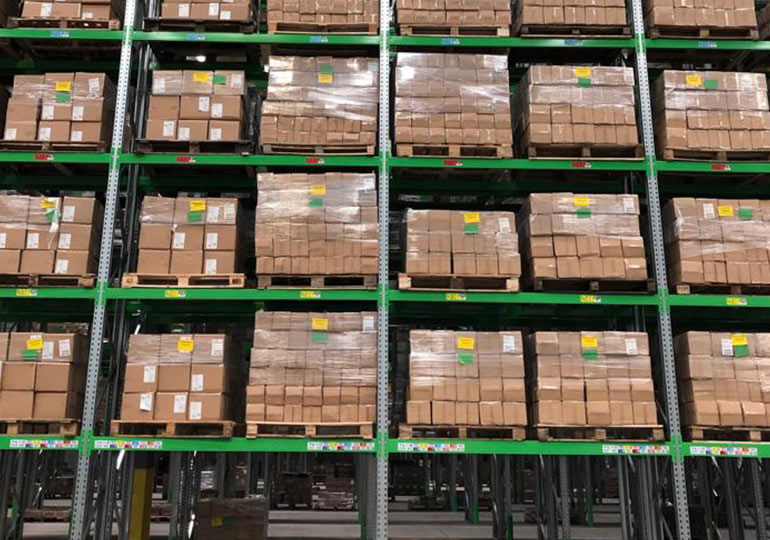

Warehouse Racking Labelling System Design & Installation

We designed a suitable labelling system for racking in a Derbyshire warehouse, then proofed all labels in conjunction with the customer and Warehouse Management System company.

Labelling: Background & Project Outline

Our client, a supplier to the service sector had taken over a new warehouse in Derbyshire and asked us to work with them to design the most suitable labelling system for the racking.

Once the sequencing and layout had been decided on, we designed and proofed all of the labels in conjunction with the customer and the WMS (Warehouse Management System) company.

Labelling: Solution

The labelling project included:

• 2,700 Base Beam Step Multi-barcode Location Labels which enable the operator to scan all levels from the floor

• 250 Drive Through Upright Frame Multi-barcode Location Labels which allows the operator to scan all levels from the floor

• 19,000 Upper Beam Location Labels with two labels per beam

• 1,200 Shelf Beam Location Labels

• 200 End Of Aisle Signs

All of the labels were colour coded to assist in easier identification of the racking levels.

The installation was completed over three stages in line with the racking build.

To discuss your project requirements, you can request a quote or get in touch with us to find out more.